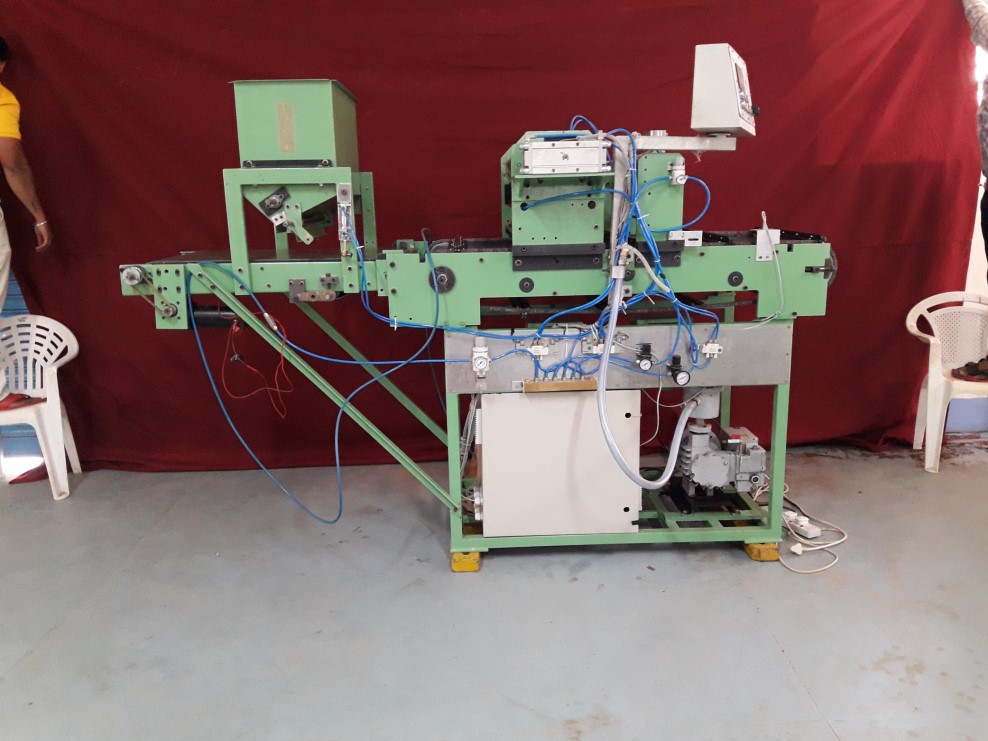

The machine designed is suitable for 98 protray cell which is widely used for vegetable nursery raising.This system consisted of protray conveyor and indexing system, dibbling unit, seed sowing unit, penumatic systems, electronic controls, vacuum pump, compressor and programmable logic controller (PLC). About eight man hours are required to sow 10 trays /hr, whereas with this machine 150 protrays/hr can be sown. With this, the seedling production cost will be reduced which will lead to reduce in input cost of farming. The present machine was calibrated for sowing tomato, capsicum, brinjal and chilli seeds. There was 94% pick up by the machine sown trays and % germination by machine and manual methods were on par.